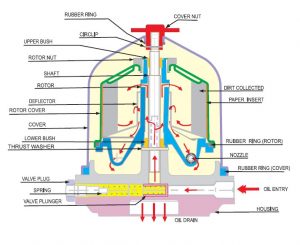

Bypass Oil Centrifuge Systems

Oil Purification to 1 micron with no filter.

For these engines and many more:

CAT 3500’S

Cummins KTA38M2 1200 HP

Cummins KTA50M2 1600 HP

Cummins QSK38M 1300 HP

Cummins QSK19M 750 HP

Cummins KTA19M3 640 HP

John Deere 6125 350 HP

John Deere 4045T 105 HP

John Deere 6068T 155 HP

We have many direct fit mounts for a variety of common CAT, Cummins and John Deere

NEW is the Dieselcraft Model 250 Direct Fit to CAT 3500 series engines.

Fuel Purifiers

Ever see this problem? We can make it go away for good if you contact us today.

Contact:

Marine Products Manager

Bob Vogel

Get a Quote

Call or click to email 772-215-8087

Recent Comments